Preventing Downtime in Manufacturing: Proactive Strategies to Safeguard Productivity and Strengthen Customer Trust

In the complex world of manufacturing, downtime is more than just a nuisance; it’s a serious financial threat. Every second that a production line unexpectedly stops, manufacturers face not just a loss in productivity but also a significant drain on resources. More critically, these interruptions can weaken the trust that forms the bedrock of relationships between manufacturers and their clients.

The financial impact of downtime is just the beginning. It reaches deeper, affecting customer relations by eroding the trust that has been carefully built over time. When operational disruptions prevent manufacturers from meeting their commitments, it places strain on these essential relationships, leaving customers frustrated and possibly looking for new partners. In today’s competitive market, where reliability and speed are key, any delay in delivery can be damaging.

Although some disruptions are unavoidable, many instances of downtime can be prevented. In manufacturing, these preventable interruptions often stem from neglect, such as overlooking preventive maintenance, inadequate employee training, or poor data management. These minor issues can accumulate over time, leading to significant setbacks that can halt entire operations.

However, manufacturers can protect themselves from these risks through proactive strategies and upfront investments. By focusing on preventive maintenance, enhancing employee training, and establishing strong data management practices, manufacturers can significantly reduce the likelihood of downtime and the damage it can cause.

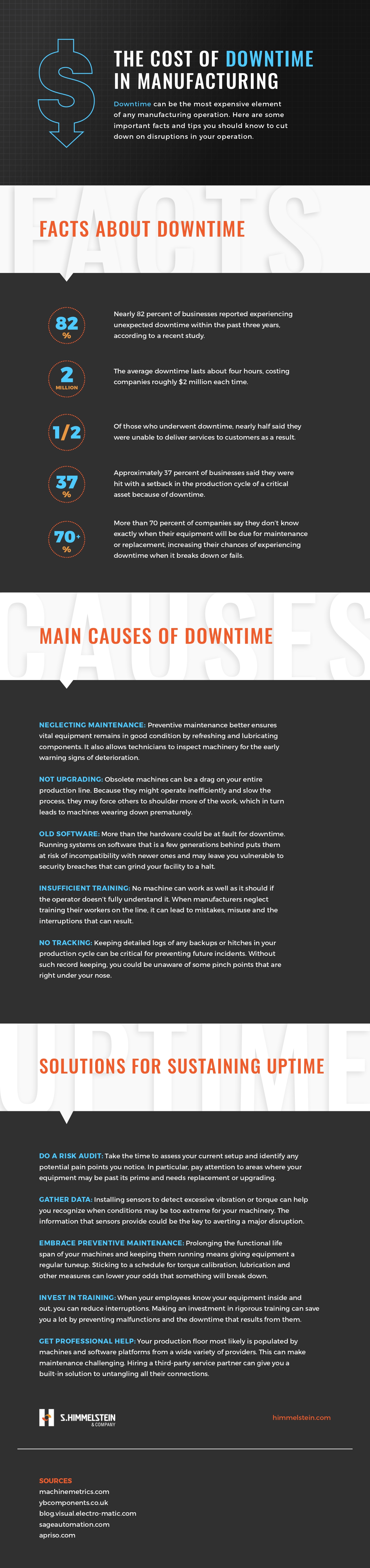

For more practical advice on preventing downtime in your facility, read on to the resource highlighted within this post. It offers valuable guidance on how to protect your operations from disruptions and underscores the importance of maintaining continuous workflows in manufacturing.

The Cost Of Downtime In Manufacturing was created by S Himmelstein and Company, one of the industry’s leading transducer manufacturers